What is a Procedure Qualification in Welding?

A Procedure Qualification in welding is a demonstration that a fabricating process, such as welding, made by a specific procedure can meet given standards. The qualification is often required by companies or organizations who need to ensure that their products or services adhere to certain quality standards.

To qualify for a welding procedure, welders must first complete a series of tests that measure the properties of the welds they produce. These tests may include measures of strength, ductility, hardness, and other mechanical properties.

What is the purpose of a procedure qualification record?

The purpose of a Procedure Qualification in welding is to ensure that the welds produced by a welder meet the required standards. This type of qualification is often required by companies or organizations that need to ensure that their products or services adhere to certain quality standards. By qualifying a welder’s procedures, companies and organizations can be confident that the welds produced will meet the necessary requirements.

Who is responsible for the procedure and welder qualification?

The welder is responsible for completing the necessary testing to qualify for the welding procedure. Once the welder has completed the testing, they will then need to prepare a report detailing the results of the testing and submit it to the company or organization requesting the qualification. It is important to note that the welder may not be the only one responsible for qualifying for the procedure; in some cases, the company or organization requesting the qualification may also be required to complete additional testing or provide reports detailing their own qualifications.

What is a Performance Qualification?

A Performance Qualification in welding, on the other hand, demonstrates that a welder can produce welds that meet the required standards.

How many Procedure Qualifications are available?

There are many different Procedure Qualifications available, depending on the type of welding being performed. Some of the more common Procedure Qualifications include:

- American Welding Society (AWS) D1.1

- American National Standards Institute (ANSI) Z49.1

- American Petroleum Institute (API) 1104

- Military Specifications MIL-STD-248

- Naval Ships’ Technical Manual (NSTM) Chapter 633

Ultimately, the choice of Procedure Qualification will depend on the specific standards that need to be met.

When should a welder renew their qualification?

A welder’s qualification must be renewed every six months, or more often if specified by the company or organization requesting the qualification.

How much does it cost to get a Procedure Qualification?

The cost of a Procedure Qualification can vary depending on the specific tests required and the number of welders being qualified. However, it is typically in the range of $500 to $1,000 per welder.

What are the benefits of having a Procedure Qualification?

There are many benefits to having a Procedure Qualification, including:

- Ensuring that welds meet the required standards

- Improved quality control

- Reduced costs associated with welding defects

- Improved customer satisfaction

Related Links

Welding Procedure Specification

List of welding codes

Welder certification

American Welding Society

Inspection and Testing for Welding Procedure Qualification

Related Videos

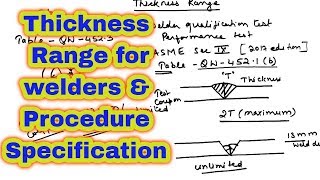

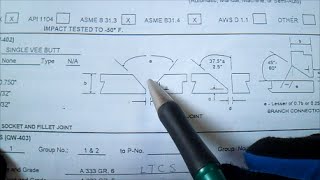

English Thickness Limit for welders and procedure qualification

English WPS and PQR - Basic Concept explained

How to write a Procedure Qualification Record (PQR)

Meeting ASME Section IX Requirements for Procedure and Welder Qualifications - Charles Patrick

What is WPS Welder - PipingWeldingNonDestructiveExamination-NDT

-

English Thickness Limit for welders and procedure qualification

-

English WPS and PQR - Basic Concept explained

-

How to write a Procedure Qualification Record (PQR)

-

Meeting ASME Section IX Requirements for Procedure and Welder Qualifications - Charles Patrick

-

What is WPS Welder - PipingWeldingNonDestructiveExamination-NDT