What is Pearlite in Welding?

Pearlite is a eutectoid alloy of iron and 85% carbon consisting of layers or plates of ferrite and cementite. It is harder than either pure iron or pure carbon, but not as hard as steel. Pearlite is formed during the cooling of austenitic steels and cast irons. It is also found in some hypereutectoid steels. Pearlite is important in welding because it can cause weld cracking.

What is pearlite steel used for?

Pearlite is commonly used in the manufacturing of:

- knives,

- saw blades,

- and other cutting tools.

It is also used in the production of wear-resistant parts such as bearings and gears.

What is austenite?

Austenite is a solid solution of carbon in gamma-iron that exists at temperatures above 723 C (1333 F). Austenitic steels are alloys that contain austenite as the primary microstructure.

What is the difference between pearlite and ferrite?

The major difference between pearlite and ferrite is that pearlite is harder than ferrite. Pearlite is also a major contributor to the hardness of steel. The presence of pearlitic microstructures in steel can make the steel difficult to machine and can also cause problems with heat treatment.

What is alpha iron?

Alpha iron is a body-centered cubic (BCC) crystal structure that is unstable below 723 C (1333 F). At atmospheric pressure, alpha iron transforms to austenite at 1333 F (723 C), but the transformation can be delayed by the presence of impurities such as carbon.

Related Links

Pearlite

ultra high strength, pearlite, wire, atom probe tomography, dissolution, carbide, Hall-Petch, strength, EBSD, texture

nglos324 – pearlite

Corrosionpedia – What is Pearlite? – Definition from Corrosionpedia

Pearlite – an overview | ScienceDirect Topics

Related Videos

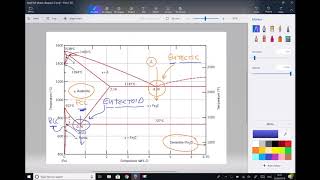

Fe -C System, Pearlite Formation

Formation of Ferrite, Cementite and Pearlite in Eutectoid Steel

Lecture 30 : Pearlite Transformation

Phase transformations in steels 9, 2014

What is PEARLITE What does PEARLITE mean PEARLITE meaning, definition & explanation

-

Fe -C System, Pearlite Formation

-

Formation of Ferrite, Cementite and Pearlite in Eutectoid Steel

-

Lecture 30 : Pearlite Transformation

-

Phase transformations in steels 9, 2014

-

What is PEARLITE What does PEARLITE mean PEARLITE meaning, definition & explanation