What is a Nondestructive Examination (NDE) in Welding?

A nondestructive examination (NDE) is the process of assessing welds and materials for their suitability without affecting their serviceability. This can be done through a variety of methods, including visual inspection, x-ray analysis, ultrasounds, and more.

There are many benefits to using NDE in welding. It can help save time and money by avoiding the need for repairs or replacements down the line. Additionally, it ensures that products are safe and fit for purpose before they reach consumers. By conducting NDE on a regular basis, businesses can avoid potential liability issues and ensure that their products meet the highest quality standards.

If you are looking for a way to improve the quality of your welding, consider investing in nondestructive examination (NDE). This process can help ensure that your products are up to standard and free from defects. NDE is an important part of any welding operation and should not be overlooked.

What’s the difference between NDT and NDE?

NDT (nondestructive testing) is a wide group of analysis techniques used to evaluate the properties of a material, component, or system without causing damage. NDE (nondestructive examination) is a subset of NDT that specifically refers to the examination of welds.

Both NDT and NDE are important tools in quality control and assurance. They can be used to detect defects, assess material properties, and verify the integrity of structures and components. NDT is typically used for industrial applications, while NDE is more commonly used in the construction industry.

No matter what your specific needs are, there is an NDT or NDE technique that can help.

What is NDE used for?

NDE can be used for a variety of purposes, including:

- detecting defects in welds and materials

- assessing the properties of materials

- verifying the integrity of structures and components

- identifying areas of concern in products

- preventing potential liability issues

What is NDE in an inspection?

NDE in inspection is the process of assessing welds and materials for their suitability without affecting their serviceability. NDE is an important part of quality control in welding, as it helps ensure that products meet the necessary standards before they are put into use.

Related Links

Nondestructive testing

Category: Nondestructive testing

American Society for Nondestructive Testing

Ultrasonic testing

What is NDT?

Related Videos

Liquid Penetrant Testing (NDT)

Non-destructive Examination

Non-destructive testing (NDT) at TWI

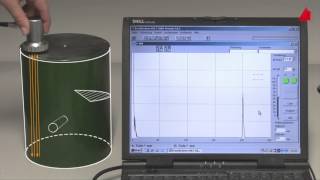

Ultrasonic Testing

Ultrasound Non-Destructive Testing Overview

-

Liquid Penetrant Testing (NDT)

-

Non-destructive Examination

-

Non-destructive testing (NDT) at TWI

-

Ultrasonic Testing

-

Ultrasound Non-Destructive Testing Overview