What is Cold Lap in Welding?

Cold lap is a type of welding defect that occurs when the weld metal does not properly fuse with the base metal or when there is an overlap between the two metals.

What causes cold lap in welding?

This can happen for a number of reasons, including incorrect welding parameters, improper cleaning of the metals before welding, or contamination of the welding area. Cold lap can cause problems with the strength and integrity of the weld joint, so it is important to avoid it.

How do you prevent a cold lap in welding?

There are a few ways to prevent cold lap, such as:

- using the proper welding parameters,

- keeping the area clean,

- and free of contaminants.

If a cold lap does occur, it can often be repaired by grinding away the defective portion of the weld and re-welding the joint.

What is overlap in welding?

Overlap is another type of welding defect that can occur when the weld metal does not properly fuse with the base metal. Overlap can cause problems with the strength and integrity of the weld joint, so it is important to avoid it.

What are the 6 welding defects?

The six most common welding defects are:

- Porosity

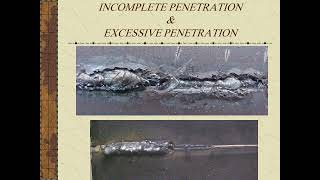

- Incomplete Fusion

- Incomplete Penetration

- Undercut

- Slag Inclusions

- Spatter

Undercut in welding

It is a condition where the weld metal is not fused to the base metal or there is an overlap between the two metals. Undercut can cause problems with the strength and integrity of the weld joint, so it is important to avoid it.

Spatter in welding

Spatter is a type of welding defect that occurs when small droplets of molten metal are ejected from the welding arc. Spatter can cause problems with the aesthetics of the weld and can also be a safety hazard.

Related Links

Avoiding cold lap | Everlast Generators

Illustration of weld toe defects; line cold lap along the weld bead… | Download Scientific Diagram

Radiograph Interpretation – Welds

Overlap (Cold Lap) – CSWIP Questions – CQ; Overlap (Cold Lap) – CSWIP Questions – CQ

Cold Lap – Shop Floor Talk

Related Videos

API 1104 Acceptance Criteria -WELDING For Pipelines

How to Detect Welding Defects with a Welding Camera

MIG Welding Basics 4 - Avoiding LOF - Ice Bucket Words

Welding Defects

-

API 1104 Acceptance Criteria -WELDING For Pipelines

-

How to Detect Welding Defects with a Welding Camera

-

MIG Welding Basics 4 - Avoiding LOF - Ice Bucket Words

-

Welding Defects